What are Volvo diesel generator sets?

Volvo diesel generator sets are high-efficiency power generation equipment with a power range of 200kVA to 710kVA, designed to meet diverse industrial and commercial power needs. Leveraging its superior technical expertise and extensive engineering experience, Volvo generator sets are widely used in critical sectors such as industrial production, commercial operations, infrastructure construction, healthcare facilities, and emergency backup.

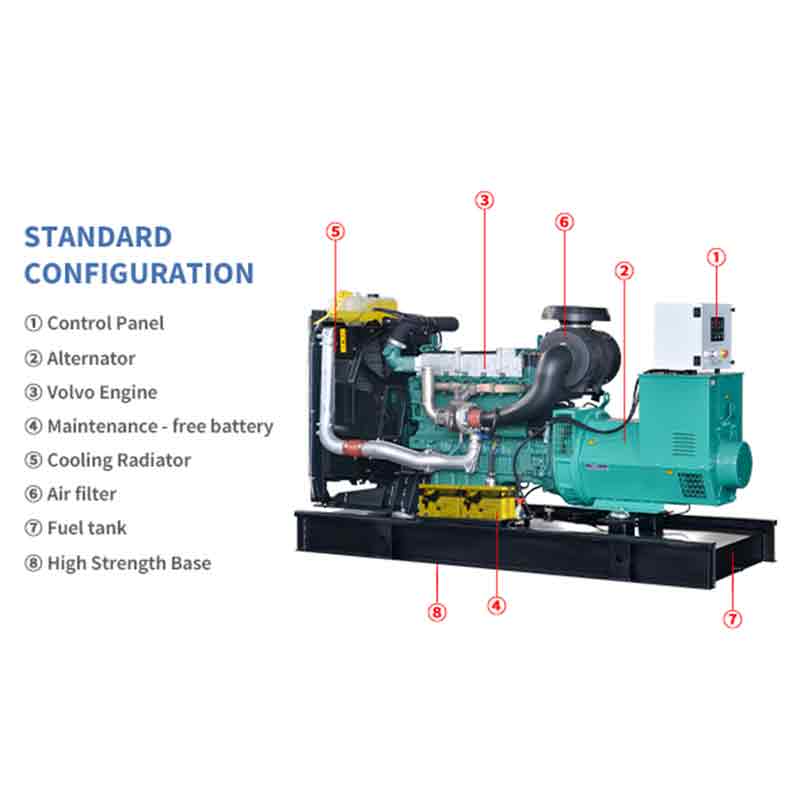

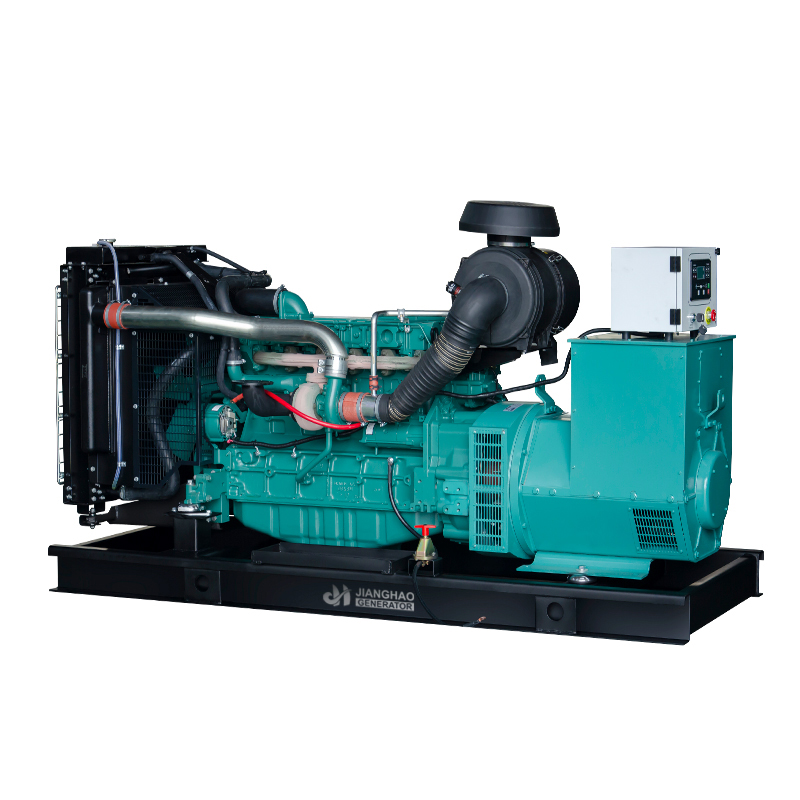

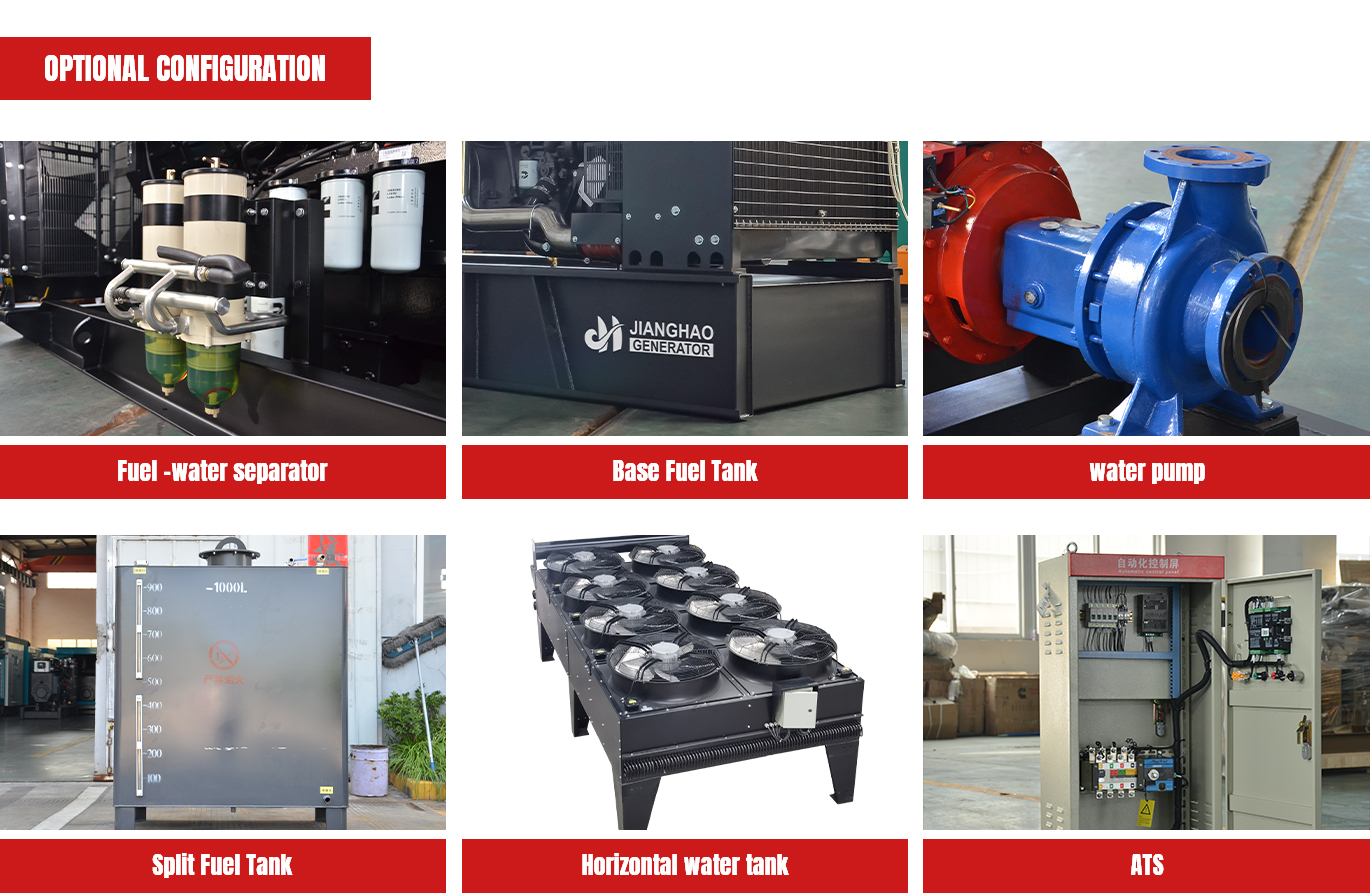

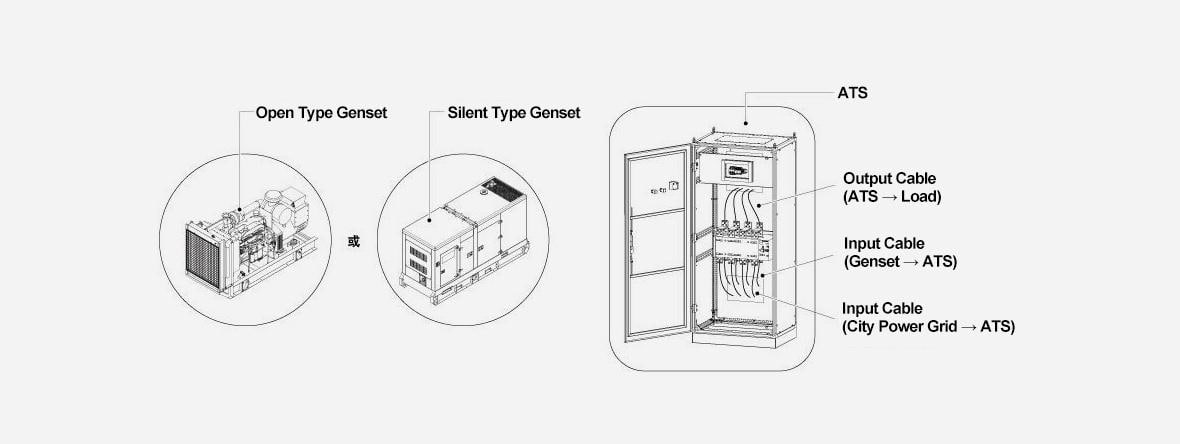

Generator series offer a variety of configurations, including open, silent, containerized, and trailer-mounted, to suit diverse installation environments and usage scenarios. Whether in urban commercial areas with strict noise requirements or space-constrained industrial sites, Volvo generator sets provide flexible solutions to ensure a stable and reliable power supply.

In terms of fuel efficiency, Volvo diesel generator sets utilize advanced electronic fuel injection and turbocharging technology to achieve an industry-leading fuel consumption of 210g/kWh, significantly reducing operating costs. Furthermore, the generator sets meet EU Stage II/III, US EPA, and China national emission standards, ensuring compliance and minimizing environmental impact.

Volvo generator sets feature a rugged, durable cast iron cylinder block and modular design, offering excellent vibration and high-temperature resistance. They can operate stably and reliably in harsh environments, ensuring high reliability and a long lifespan.

What are the core technical features of Volvo diesel generator sets?

Volvo diesel generator sets, with their exceptional technological innovation and sophisticated engineering, set the benchmark for efficiency, environmental friendliness, and durability in the industry. Their core technologies not only significantly improve fuel efficiency and reduce operating costs, but also extend equipment life and simplify maintenance through advanced structural design and optimization of key components. These technological advantages enable Volvo generator sets to operate stably in diverse operating conditions, meeting the demanding needs for high-quality power supply in diverse sectors such as industry, commerce, and infrastructure.

Advanced Electronic Fuel Injection Technology: Volvo generator sets utilize a high-precision electronic fuel injection system that monitors and adjusts fuel injection quantity and timing in real time, ensuring more complete and uniform combustion within the engine. Compared to traditional mechanical injection systems, electronic injection technology not only improves fuel efficiency but also significantly reduces exhaust emissions, helping the unit achieve a fuel consumption standard as low as 210 grams per kilowatt-hour, effectively saving users fuel costs.

Turbocharging and intercooling system: The unit is equipped with a turbocharger and intercooler system, which increases engine air intake volume while reducing intake temperature, optimizing the air-fuel mixing efficiency. The four-valve/cylinder design further enhances airflow, ensuring a more complete and efficient combustion process. Turbocharging technology not only enhances engine power output and responsiveness, but also ensures stable and efficient operation under various load conditions.

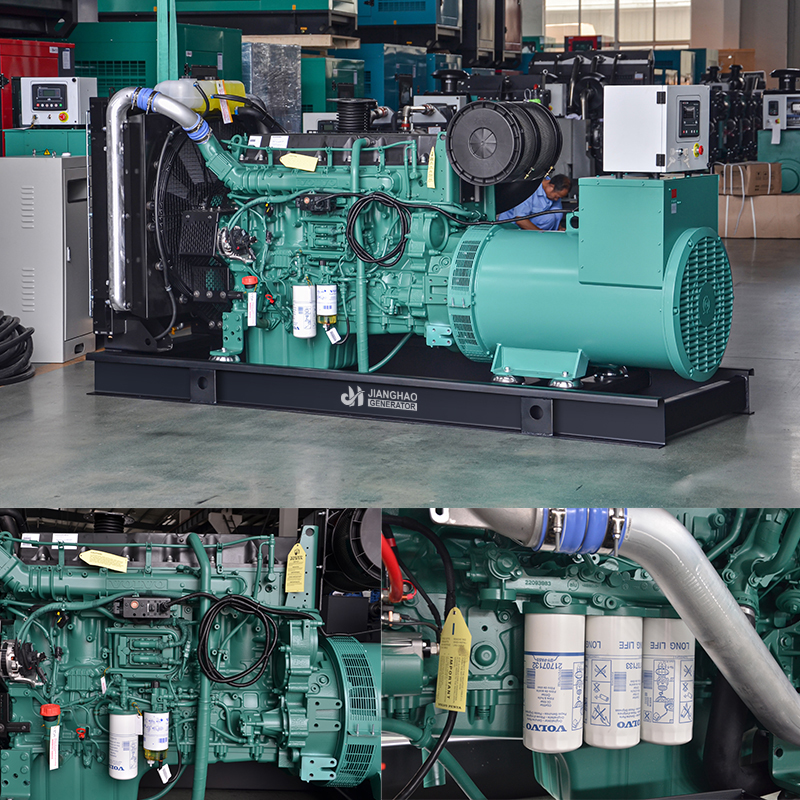

Wet-replaceable cylinder liner design: Volvo diesel generator sets utilize wet-replaceable cylinder liners. This design allows users to easily replace worn cylinder liners during maintenance without having to replace the entire cylinder block, significantly reducing maintenance difficulty and cost. Direct contact between the cylinder liners and the coolant helps dissipate heat, reducing the risk of engine overheating, extending the overall engine life, and ensuring long-term stable operation of the unit.

Oil-cooled piston technology: The unit's oil-cooled piston design directs the oil to the piston bottom, effectively lowering piston operating temperatures and reducing deformation and wear caused by high temperatures. This not only improves engine durability and reliability, but also further reduces maintenance frequency, significantly saving users significant maintenance costs. It also enhances equipment stability and operating efficiency under high-load conditions.

What are the advantages of Volvo diesel generator set structural design?

Volvo diesel generator sets are designed with user convenience and affordability in mind. Through a modular structure and high-quality materials, maintenance is efficient, simple, and cost-effective. This not only effectively reduces equipment downtime and maintenance costs, but also significantly increases unit reliability and service life. The following are several key maintenance advantages of Volvo generator sets:

Modular Structural Design: Volvo diesel generator sets utilize an advanced modular design concept, with key components such as the engine, generator, and control system arranged in a scientific and rational manner. This streamlines and standardizes the connections between components. This design not only enables maintenance personnel to quickly locate faults, quickly remove and replace damaged parts, but also greatly simplifies the maintenance process. The modular structure effectively shortens maintenance and overhaul time, significantly reducing equipment downtime, ensuring continuous production and operations for users and avoiding the financial losses caused by extended downtime.

Replaceable wet cylinder liner design: The unit utilizes a high-performance wet cylinder liner design, which provides excellent heat dissipation and wear resistance, ensuring engine stability under prolonged high-load operation. If the cylinder liner becomes worn during use, it can be replaced individually without disassembling or replacing the entire cylinder block, significantly reducing repair complexity and overall maintenance costs. This design not only extends the overall engine life but also significantly improves the economic benefits and lifecycle of the equipment, helping users reduce long-term operating costs.

High-quality materials and durable craftsmanship: Volvo strictly selects high-quality materials with excellent wear and corrosion resistance for key components. These materials can effectively withstand physical and chemical attacks in various harsh operating conditions, ensuring the overall durability and long-term stability of the unit. High-standard manufacturing processes ensure the generator sets can operate continuously in extreme environments such as high temperature, high humidity, and heavy dust. This reduces equipment failure rates and maintenance frequency, saving users significant human resources and maintenance costs, and increasing the overall economic value of the equipment.

Intelligent Monitoring and Early Warning System: Volvo diesel generator sets are equipped with an advanced intelligent monitoring system that collects and monitors key operating parameters such as temperature, pressure, speed, and load in real time. The system automatically analyzes data to promptly identify potential failure risks and, through early warning mechanisms, alerts users to proactively perform maintenance and inspections. This preventative maintenance effectively avoids the risk of unplanned downtime caused by sudden equipment failures, ensuring the generator sets are always in optimal operating condition, thereby ensuring continuous and stable power supply and improving the overall user experience and equipment safety.

English

English русский

русский Español

Español عربى

عربى